Trenchless Service Line Replacement

Trenchless Service Line Replacement

Fix Potential Lead Issues in Your Water Supply with Trenchless Service Line Replacement

In April of 2014, in an effort to save costs on the city’s water supply, the city of Flint, Michigan stopped buying water from the neighboring city of Detroit and began pumping water from the Flint River in anticipation of connecting to a new regional water supply that was being developed from Lake Huron. What happened next is a thing of nightmares for water utilities and their customers across the country.

Flint Water Crisis

Despite immediate health symptoms reported by its residents, Flint continued to state that the Flint River water being delivered through their water supply system was safe. The city even passed on the opportunity to reconnect to the Detroit water supply, which would have removed the issue with safe, clean drinking water. Bacteria levels and chlorination were at the heart of the lead crisis. When Flint River water bacteria levels were too high for human safety, the water utility added more chlorine to the water, but failed to add the federally-required anti-corrosive agents. This caused significant amounts of lead to leach out of the city’s pipes, fittings and fixtures and into corrosive water, contaminating the water supply with waterborne lead.

The issues were truly mind-boggling as they came to light. Take the case of LeeAnne Walters, a stay-at-home mother of four and Navy wife in Flint, MI, who had lead levels as high as 13,200 parts per billion (PPB), more than double the 5,000 PPB at which point the EPA considers water to be hazardous waste. This level equates to about 50 milligrams of lead per gallon. Mrs. Walters sent her water for testing because she was worried that the dark sediment in her water was making her and her children sick and giving them rashes, especially her three-year-old twin sons. The city initially stated that the lead must be in her home’s pipes and fixtures, but Mrs. Walters knew this couldn’t be true: when the family purchased their home, its old plumbing lines had already been stolen for salvage. They had been completely replaced with lead-free plastic piping.

When the Walters family’s service line was replaced by city workers following the first rounds of testing, an EPA expert returned in time to take a piece of the line for testing. Tests confirmed it was pure lead – confirming Mrs. Walters’ fears that lead was contaminating water in transit to her home. She had good reason to fear for her children’s well-being. Two years later, twin son Gavin was 35 pounds compared to his identical brother Garrett’s 53 pounds. Gavin’s growth had been stunted by the lead in the water. Four years later, her twin sons were still in occupational, physical and speech therapy. They may never recover fully from their early lead exposure and poisoning. A Flint, MI principal has since noted that the school district’s special education caseload has doubled since the water crisis began.

There can be no doubt that lead in our water supply can lead to significant human and animal health concerns. Following the Flint crisis, water utilities across the country scrambled to ensure that a situation such as this could not come about again. But why is lead such a serious issue with water supply lines? Why do we need to take strong action to make sure that people are protected against a repeat of the Flint water crisis? How do we protect against similar issues and defend communities against the perils of lead poisoning? You’ll find the answers you need below.

The Severity of Lead-in-Water Issues

During the Flint water crisis, Mayor Karen Weaver initially estimated that the city would need to replace 15,000 water service lines that were galvanized steel or lead, a figure which was later upgraded to 18,000 per a landmark case settlement and then increased to an estimated 29,100 lines when a study by University of Michigan was released. That figure represents 53% of the city’s 55,000 service lines at the time of the estimates, making a huge impact on the city’s budget. Despite the financial challenges and a cost of over $100 million, leaving the city dependent on state and financial aid to protect its residents from lead service lines, the city of Flint has continued to act. As of September, 2022, Flint had completed 27,428 water service line excavations and had 1,600 lines remaining to go. At 95% completion, the progress is significant, and Flint has entered the final phase in its lead service line replacement project. The city’s water system has tested within state and federal standards for lead since July 2016, and in 2018, Michigan adopted the toughest lead rules in the nation related to lead in drinking water.

How many residents in other cities and states are being impacted by lead service lines and water contamination? Early in 2019, testing in Newark, New Jersey revealed over half of tested households having unsafe lead levels in their drinking water. In 2019, the city began a labor- and cost-intensive process is tearing up streets around the area to dig up and inspect the old service lines, replace them if lead content is found, then re-bury the line and re-pave the road. During the process, the city switched to a different anti-corrosive agent in the source water, leaving the treatment plant lead-free and reducing lead leaching. With a $120 million bond to accelerate their efforts, Newark, NJ completed the lead service line replacement project with over 23,000 lines replaced by February 2022. In 2023, East Newark will begin a similar project with new federal funding designed to accelerate lead service line replacement for public health.

Taking Preventative Action

Many cities are getting ahead of the issue before it becomes a problem. Buffalo, New York is taking advantage of state funding for initiatives to remove lead from water utility systems by replacing up to 200 lead supply lines every year as they break or leak, though there have not been any serious issues to date with lead poisoning or lead levels in the city water. Property owners who do not have supply line coverage in their homeowner’s insurance will have the cost of replacement covered by the city. Milwaukee is using a city initiative to replace up to 1,000 supply lines per year, though with an estimated 75,000 lead supply lines in the city, the progress is extremely slow at best. To date, all of the city’s daycare and child care centers that have lead supply lines have had them replaced, protecting one of the most vulnerable populations from lead poisoning.

Denver is currently working on one of the most ambitious initiatives, estimated to take 15 years at a cost of $500 million. Unlike many other water utilities that are only replacing water lines when an issue has appeared, the city plans to systematically replace all of their lead water supply lines, estimated at between 50,000 and 90,000 at a rate of about 5,000 lines per year. The city has already been removing lead lines when they encounter them during construction, and Denver Public Schools has taken proactive steps to remove all lead supply lines from their schools. At the same time, Denver’s city water utility is taking steps to prevent lead leeching in the existing lines while the process is ongoing, in an approach similar to Newark’s use of more effective anti-corrosive treatments. If the initiative passes, the utility will issue water filters to tens of thousands of affected homes and making further adjustments to alkalize the water, as lead is much more likely to leech out in water with an acidic pH.

BUFFALO, NY AND DENVER, CO ARE JUST A FEW EXAMPLES OF SAFE WATER INITIATIVES SPREADING ACROSS THE COUNTRY!

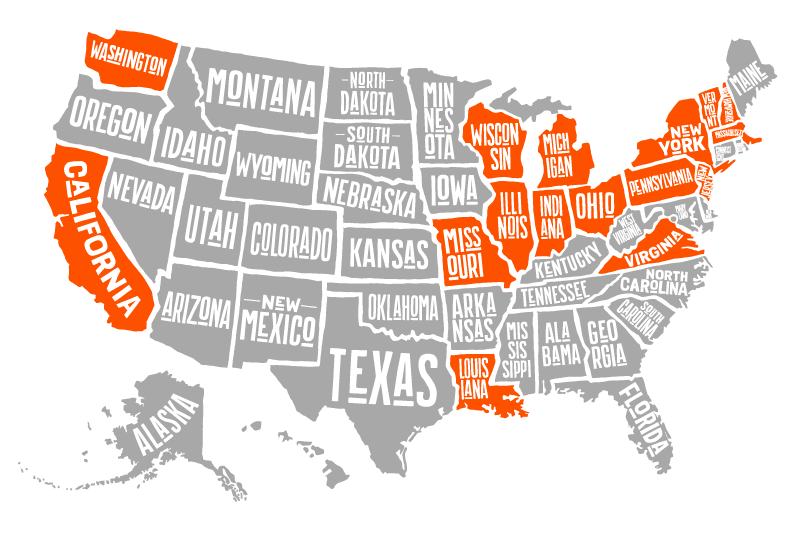

To date, at least 30 states have begun initiatives to remove lead supply lines from their borders, and federal initiatives have been created to accelerate these efforts. At least seven communities, including Newark, NJ and Flint, MI, have completely replaced all their lead supply lines. Eventually, federal regulations will require replacement of every lead service line nationwide. This process can be complicated, as ownership of the supply line is different from city to city and state to state, with either the utility or the property owner claiming ownership of the lines. It can also be a prohibitively expensive process, as many municipalities still dig up their old supply lines rather than using more modern methods of replacement, such as in-place service line pulling for a less expensive, trenchless approach.

- Alabama

- Arizona

- California

- Colorado

- Connecticut

- Delaware

- Illinois

- Indiana

- Kansas

- Louisiana

- Massachusetts

- Michigan

- Missouri

- Nebraska

- New Hampshire

- New Jersey

- New York

- North Carolina

- Ohio

- Oklahoma

- Pennsylvania

- Rhode Island

- Tennessee

- Utah

- Vermont

- Virginia

- West Virginia

- Washington, DC

- Washington

- Wisconsin

What are the Federal Lead Rules?

The EPA has a specific regulation in place, called the Lead and Copper Rule, which regulates the amount of lead and copper allowed be present in drinking water provided by water utilities and similar organizations. Though it has undergone some changes since its inception in 1991, it essentially dictates that no more than 15 parts per billion (PPB) of lead or 1.3 parts per million (PPM) of copper are allowable in drinking water in more than 10% of customer taps that are sampled. The number of taps sampled each testing cycle is dictated by the number of structures the water utility serves. If the EPA limits are exceeded, there are a number of remedies that must be undertaken in order to protect public health and well-being. In the Flint water crisis, there were questionable testing procedures used, such as letting the water flow for several minutes before collecting a sample rather than collecting the first water that was drawn from the fixture; this method decreases the level of lead that would show up in the sample.

The EPA has a specific regulation in place, called the Lead and Copper Rule, which regulates the amount of lead and copper allowed be present in drinking water provided by water utilities and similar organizations. Though it has undergone some changes since its inception in 1991, it essentially dictates that no more than 15 parts per billion (PPB) of lead or 1.3 parts per million (PPM) of copper are allowable in drinking water in more than 10% of customer taps that are sampled. The number of taps sampled each testing cycle is dictated by the number of structures the water utility serves. If the EPA limits are exceeded, there are a number of remedies that must be undertaken in order to protect public health and well-being. In the Flint water crisis, there were questionable testing procedures used, such as letting the water flow for several minutes before collecting a sample rather than collecting the first water that was drawn from the fixture; this method decreases the level of lead that would show up in the sample.

The EPA’s rules were put in place to help minimize the effects of lead in the water, which has been known to cause issues with memory, brain damage, kidney issues and other health effects. Excess copper in the water can have ill effects, too, including digestive distress, liver and kidney damage, and complications from Wilson’s Disease in populations that are genetically predisposed to this illness. When water testing shows an excess of lead above the acceptable action limit of 15 PPB, the water utility is required to begin providing educational materials as part of their community outreach to help customers understand the potential health effects of exposure, sources of lead exposure and how to lower their exposure to lead. They are also expected to make special efforts to reach out to at-risk populations, such as children and pregnant women, in whom the effects of lead poisoning may appear at significantly lower levels. Press releases are an expected part of this outreach process. Overall, the outreach must begin within 60 days of the above-limit or action level testing and continue until follow-up testing has shown the waterborne lead levels to have dropped beneath the action level for a specified period of time.

Another issue with exceeding the action level for waterborne lead is the addition of source water monitoring and treatment to help determine how the source water is contributing to the overall lead levels in the water. Corrosion control treatments are also used to limit the amount of lead from leaching from existing pipes and infrastructure into the water by reducing the corrosiveness of the water being transported. If, with these two systems in place, the levels of lead continue to remain above the action level of 15 PPB, the EPA can then require the water utility to begin removing and replacing lead service lines. As with the public education mandate, these processes can stop once follow-up testing has shown that the waterborne lead levels have been reduced to beneath the action level. However, the impact on the public goodwill remains, forcing many water utilities to continue replacing lead supply lines in order to counteract the bad press they’ve received due to having high lead levels in the water in the first place.

General Information About Lead in Drinking Water

The first question many consumers ask when lead is reported in drinking water is how it gets there in the first place. Within the home, it can come from a wide range of possible sources. It can show up in solder for copper pipes that were installed prior to 1986, when lead was still allowable in plumbing solder. Solder that has been manufactured for this purpose since 1986 is required to be lead-free under the Safe Drinking Water Act. Some fixtures in the home may have been made prior to various lead-free manufacturer requirements or may be below the threshold for the requirements at the time, but may still contain a small amount of lead, which is commonly added to brass during the casting process to help prevent voids from forming within the casting and to make the tooling process easier. Galvanized iron pipe, though it does not specifically contain lead, may allow lead particles to attach to the inner surfaces of the pipe, which may eventually detach and enter drinking water. Lead service lines and goosenecks or pigtails may be used either for the entire run of the service line from the meter to a home, or for short distances to connect the service line to the water main, a common practice when several water service lines are expected to be connected at the time that the main is being installed, to minimize future digging and repaving processes.

The first question many consumers ask when lead is reported in drinking water is how it gets there in the first place. Within the home, it can come from a wide range of possible sources. It can show up in solder for copper pipes that were installed prior to 1986, when lead was still allowable in plumbing solder. Solder that has been manufactured for this purpose since 1986 is required to be lead-free under the Safe Drinking Water Act. Some fixtures in the home may have been made prior to various lead-free manufacturer requirements or may be below the threshold for the requirements at the time, but may still contain a small amount of lead, which is commonly added to brass during the casting process to help prevent voids from forming within the casting and to make the tooling process easier. Galvanized iron pipe, though it does not specifically contain lead, may allow lead particles to attach to the inner surfaces of the pipe, which may eventually detach and enter drinking water. Lead service lines and goosenecks or pigtails may be used either for the entire run of the service line from the meter to a home, or for short distances to connect the service line to the water main, a common practice when several water service lines are expected to be connected at the time that the main is being installed, to minimize future digging and repaving processes.

In Flint’s situation, the lead in their system only became a problem when they began using polluted water from the Flint River in place of the Lake Huron water the water utility had been pumping from Detroit. The polluted water had a number of issues that required correction. An outbreak of Legionnaire’s disease, and several tests revealing the presence of E. coli and high levels of coliform bacteria in unacceptable amounts for human health required the water utility to add extra amounts of chlorine to the water, making the water more corrosive than in the past. Federal law requires anti-corrosive chemicals to be added to water that is treated with corrosive agents or that is known to be corrosive at the source. However, Flint did not take this step to reduce the water’s pH to a less corrosive amount. As the corrosive water passed through its system, it came into contact with lead fittings, supply lines and other sources of lead which then allowed that lead, which had remained in the system without issue previously, to be leached into the water supply, causing significant harm to the water utility’s customers.

Unfortunately, as residents in Flint soon came to learn, a number of very serious health effects can occur after exposure to lead in drinking water. Lead is a toxic substance of which the EPA has a goal of zero exposure, but is actually tolerated at very low levels in drinking water due to the virtual impossibility of removing the lead completely in a cost-effective manner. However, fetuses, infants and young children are especially susceptible to lead in their environment and bodies, with strong effects even at far lower levels of exposure than would typically affect adults. Exposure leads to a wide range of physical, mental, emotional and developmental issues in children. Lead exposure can cause damage to the central and peripheral nervous system, learning disabilities, stunted growth, hearing impairment, anger control issues and impaired function and formation of blood cells. Indeed, it was a pediatrician in Flint who began putting together the first scientific documentation of elevated lead levels in the city’s children, which has resulted in an epidemic of behavioral and learning problems, lower IQ, hyperactivity, anemia, slower growth rates and hearing problems. In the unborn, lead exposure in the womb can lead to reduced fetal growth and premature birth – in those that survive to that point. Lead has been linked to miscarriage, stillbirths and infertility in pottery factory workers well over a century ago. Lead also has a tendency to be mistaken for calcium by the body, literally forming a baby’s bone tissues out of the toxic substance.

There was one very common question during the Flint water crisis: is it safe to shower or bathe in the lead-contaminated water? The EPA states that bathing and showering should be safe for children and adults, because human skin doesn’t absorb the lead in the water. However, it should be noted that the first signs noted by Flint residents included rashes that would appear on children’s skin when bathing in the lead-contaminated water of the city. Adults who spent significant time bathing in the water would also develop rashes, though not as severe. Many of these residents noted that the rashes would stop appearing when they switched to cleaning themselves with bottled water or showering/bathing with other water sources. Whether this was due to the presence of lead in the water or simply the corrosive water itself that caused the lead to be leached into the water is up for debate, but in either case, medical symptoms like this should not be ignored. It is certainly safer to run the water for several minutes to clear out the most heavily contaminated water that has been sitting in the system collecting lead before beginning bathing or showering – and always prevent children from drinking bath water.

Challenges Faced by Water Utilities in Replacing Lead Service Lines

With these serious issues at hand, many consumers wonder why water utilities are not simply replacing all lead service lines still in use. Unfortunately, the depth of the issue is tough to grasp without digging into the details, and the picture is a complicated one. Service line replacement is a labor- and cost-intensive process. These issues can make the process prohibitive for many water utilities, which is why state and federal initiatives to help with the expense are helping many municipalities move forward with what would otherwise be an impossible task. The three top issues involved in replacing these service lines are the time investment to complete this work; the expense that strains already-tight municipal budgets; and the effects of public inconvenience as the lines are dug up and replaced.

Lead service lines must be identified before they can be replaced. Not all cities have comprehensive records of where these lines are installed; identifying lines and tracing them to their origins at the water main (often buried beneath a roadway) can take time. Once the line’s location is properly marked, other utilities in the area must also be marked, to prevent accidental damage to those lines. Notices and permits must be posted or acquired before digging commences. A backhoe or other heavy equipment is brought in and the street blocked off while the old supply line is dug up, with hand digging taking place around other utilities to prevent damage. The old line is shut off and disconnected from both the water main end and the house end, and then a new supply line is placed, connected, tested for leaks and finally re-buried. Finally, repairs to the surface pavement, turf and other areas must be completed.

Sounds expensive, right? It is. Water service line replacement typically runs several thousand dollars per line, and the expense is rising every year. As wages and material costs continue rising, it’s projected that the cost of replacing a supply line will go up by 3-5% every year – at the same time that citizens are fighting tax increases that may support these increased expenses. Equipment, fuel, parts and materials are also rising in cost. There are legal costs to consider, too, like the rising cost of litigation when water utilities – such as Flint, MI – are found at fault for not properly handling waterborne lead issues.

A big consideration for water utilities is the public inconvenience created by the process of service line replacement. For a residential service line, water must be shut off to the home, inconveniencing the homeowner. If the water line is buried under the street, the street must be shut down, inconveniencing neighbors. If it’s a busy street, the traffic must be routed around the work, which can lead to traffic accidents or congestion and increased police response required. At the same time, more complaints are being called into the city and the water utility, even as they try to have all hands on deck and working hard in the field to complete the work quickly so that they can get on to the next project on the list. This entire process makes the removal of lead supply lines difficult at best for water utilities.

However, there are other options available to make the process faster, easier and less expensive while reducing customer complaints. Using a service line puller can bring the process of changing lead service lines within the grasp of even the smallest water utilities. This allows you to meet the demands of consumers who want their service lines replaced while minimizing the impact on your water utility’s budget, task list and repair process. In the past, the effectiveness of these tools has been limited by their design, which has often been engineered to only work in soft, loose soils, but new options are available.

How to Replace a Service Line with a Service Line Puller Kit

New Concept Tools was formed to provide the water utility industry with better options for safer, more effective operations, and our service line puller kits are an exceptional example of that dedication to purpose.

How Can the New Concept Tools (NCT) Service Line Puller Kits Help?

How Do NCT Service Line Puller Kits Work?

What if you could replace those old, corroded lead service lines with 90% less digging? What if you could avoid stopping traffic while spending hours removing the old line and getting the new one in place? What if you could avoid most of the expense of re-paving roads after changing out a service line? Would that make the process of changing out service lines easier, less expensive and less aggravating for your water utility? Of course it would! But how does it work? By using our specially-designed Service Line Puller Kits.

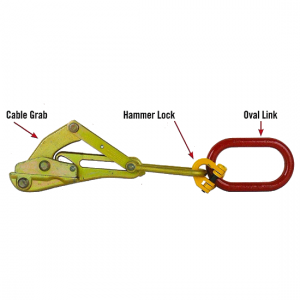

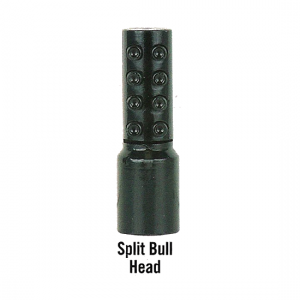

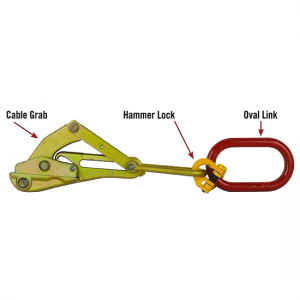

New Concept Tools isn’t the first company that has developed a service line puller, but our dedication to developing superior tools for the water utility industry means that we’ve developed one of the best service line puller kits available in the industry. Rather than focusing on a single pipe size and type, our two available kits each handle a range of pipe sizes and materials from 3/4″ to 2″. The kits include the Split Bull Head puller, strong cables in multiple lengths, starting and adapting tools, a cable grab with a hammer lock and oval link that attach to a piece of heavy equipment for pulling, and a range of different heads for attaching and pulling the new pipe.

The Service Line Pulling Process

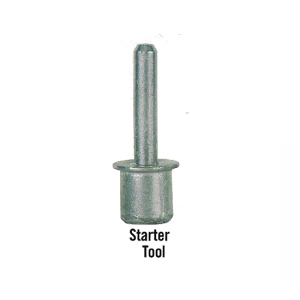

When you use an NCT Service Line Puller Kit, you need to dig holes to access the ends of the supply line – but not the entire line. With holes dug, make sure the water supply is turned off and disconnect the supply lines at both ends, cleaning up about 6-8″ of the service line and then cutting it off by using a wheel cutter at each end. If the ends have been damaged, the starter tool can be used to return them to round. A cable is then passed through the existing supply line, which is then attached to the Split Bull Head carrying the new supply line on its back end. The Split Bull Head should be assembled with anti-seize compound applied to make it easy to assemble and disassemble. Our Split Bull Head is detachable instead of permanently attached, as it allows for easy field repairs if you experience cable breakage. The attachment process simply involves tightening a few Allen head screws. If the structure end of the supply line passes through the home’s wall, you’ll need to make sure there’s enough clearance for the Split Bull Head and related tools to pass through the wall into the soil on the other side.

Our kit allows you to attach copper or steel pipe directly to the Split Bull Head for pulling, either by direct threading or by using a brass compression coupler. You can also use the Split Bull Head with our plastic adaptor that allows you to pull a range of plastic piping through behind the Split Bull Head. The other end of the cable is attached to the cable grab, which is attached to the backhoe or other pulling equipment with the hammer lock and oval link. The Split Bull Head is then pulled through the existing supply line in a straight line using a backhoe or other heavy equipment. As it passes through the existing lead supply line, it either splits, expands or pulls that old line out while drawing the new supply line in place behind it. When the equipment reaches its maximum draw, the cable is released from the cable grab, the old pipe that is sticking out is cut off and removed, and the cable grab is moved to a location near the cut on the cable and the pipe is pulled again until the new line is in place. Within a very short amount of time, the old supply line is out of the way, and the new supply line has been laid in place and is ready to be connected and tested for leaks. Once it’s installed, simply backfill the holes, make a small paving repair if needed and go about your day, getting to the next task on your list.

Service Line Puller Kit: Instruction Manual

This service line puller kit manual will provide you with all the necessary information to use your kit properly. Inside you’ll find information on:

- Included Products

- Removing Different Pipe Types

- Product Numbers

- Instructions

Cost-Effective Supply Line Replacement

With the NCT service line puller kit, because your water utility is not spending a lot of extra time digging, refilling and repairing pavement, the cost for replacing lead service lines is minimal. In the past, service line puller kits have only been available to work with one size and pipe material. Our service line puller kits work with 3/4″ and 1″ pipe in our small-diameter kit and 1-1/4″, 1-1/2″ and 2″ pipe in our large-diameter kit, and both kits can be used to pull not just lead supply lines – but also steel, copper or plastic pipe, making it a tool that will work well for your water utility long into the future for a variety of needs.

Our detachable Split Bull Head allows you to make fast field repairs if a cable breaks, instead of having to wait for a replacement cable and bull head to show up like some of our competitors’ models. The cable grabber makes changing the position of the grabber on the cable simple, so that you can quickly pull more cable once the old pipe section from that pull is removed. The hammer lock keeps the cable grabber safely and securely attached to the oval link, providing a safer alternative to just looping the cable around a backhoe bucket (this makeshift solution can cause dangerous wear, tear and fraying on your cable). This reduces damage and provides a safer working environment for your crew. You spend less time excavating and repairing your excavation because you simply pull the new pipe through or behind the old one as it goes, which means fewer unhappy customers because the job is completed more quickly. It also means you’ll see reduced costs from repair materials and labor, which makes it easier and faster to get through the process of replacing lead service lines, allowing you to replace more of them every year.

A Truly Trenchless Solution

But will the New Concept Tools service line puller kit work in your water utility’s soil conditions? We have a video that shows how quickly and easily the process works, and some viewers are concerned that it’s only this easy because the dirt must be too soft. Not true! We’ve designed our kit to be a heavy-duty solution that works in all soils, whether you’re dealing with loose sand, heavy gravels or tight-packed clay. We use strong, heavy-duty cables and components to give you the solutions you need, despite heavy soil issues.

No matter what your soil conditions are, you can draw the service line puller kit through that soil to remove, expand or split the old service line and pull the new line behind it quickly and easily. Like all of our quality water utility tools, our Service Line Puller Kit is designed to provide maximum results with superior safety and easier usage than other options available on the market. Its strong, solid construction will allow you to pull new supply lines through virtually any soils you can find in your water utility, giving you an inexpensive trenchless pulling solution no matter your local conditions.

A Glance at Each Tool in the Service Line Puller Kit

The trenchless Service Line Puller Kit comes in two different sizes to handle a range of pipes, providing you with a wider range of versatility. We know that water utilities typically have a range of different supply line materials, so our kits each include all the tools you’ll need to get the job done quickly and effectively, whether you’re pulling lead, copper, steel or plastic piping. We also offer replacement parts if you lose or misplace portions of your kit. Here’s a quick look at each of the tools that offered in our kits.

Split Bull Head:

Our proprietary Split Bull Head design provides you with superior pulling power. It has an improved grabbing design, and the split head allows you to directly attach the head to the cable’s plain end. If you have a cable break in the field, you can simply detach the Split Bull Head from the broken cable, reattach it with either bolts and nuts or screws to the new cable’s end and get back to work.

Strong Cables

The smaller kit, designed for removing 3/4″ and 1″ supply lines, has three different cable lengths of 3/8″ cable that are available at 50′, 75′ or 100′, which provides you with options depending on how long your average supply line tends to run. The larger kit, which handles 1-1/4″, 1-1/2″ and 2″ supply lines, has these same lengths available, but in stronger 1/2″ diameter, providing the extra pulling power you need to get the job done with larger-diameter service lines. Every kit includes a second cable in case you have a cable break on the job site, saving a trip to the hardware store or waiting for a shipment to arrive.

Hammer-Lock and Oval Link

The oval link supplies a flexible connection to the backhoe or other heavy equipment, while the hammer lock provides a solid, safe connection between the two pieces, preventing injuries that can happen when a cable that is simply wrapped around a backhoe bucket is frayed and stressed enough that it finally snaps.

Cable Grab

At the heavy equipment end of the cable, the combination of the oval link, hammer lock and cable grab make the process of pulling the old service line out simple. The cable grab is quickly and easily removed from the cable after a pull, allowing you to cut and remove the pulled length of pipe, then is quickly reattached further down the cable for the next pull without bending, stressing or fraying the cable, improving worker safety.

All-In-One Storage

When you get new tools, it’s very easy to say that you’re going to keep everything together, but that doesn’t always happen. Cheap plastic storage or fabric bags make it easy for pieces to become dislodged, making it hard to keep all of those pieces where they belong. Our Service Line Puller Kits come in a strong steel box for long-term storage. This means it’ll handle all the abuse you can throw at it in the field while still keeping all of your parts together in a single, easy-to-carry container. Lost kit parts are a thing of the past!

Service Line Puller Kit

With a backhoe and the Service Line Puller Kit you can remove old and failing service lines and replace them with new tubing with minimal digging, less property damage, reduced downtime and with less expense than digging the entire service and replacing it.

The benefits Of Trenchless Service Line Replacement with our service line puller kit include far less digging than conventional methods, less damage to private property, no trench settlement, reduced downtime for the customer’s service. The kit can pull old copper, lead, steel, and plastic service lines. It can also pull a new service line while splitting old plastic tubing at the same time.

New Concept Tools’ is Dedicated to Developing Stronger, Safer, and Easier Tools for the Water Utility Industry

The water tragedy in Flint, Michigan has opened water utility customers’ and officials’ eyes across the country and around the world. The children who have been impacted by waterborne lead in Flint may never grow to lead full, productive lives, but will quite possibly bear the burden of their exposure for the rest of their lives. The Walters twins still wonder and ask, years later, whether the water they are being given to drink is good water or bad water, an experience that will stay with them for decades to come. The strong coverage of this situation has changed how our customers view their water utilities and city governments. The basic trust that the water coming out of their tap is safe for their families to drink has been drastically reduced.

No longer are customers willing to remain complacent, trusting that their water utility is always doing the right thing in the public’s best interest. To stay on top of this trend, water utilities are scrambling to replace lead supply lines, but often at a high cost of labor, time, public goodwill and the expense of the process. To be left behind during this process means earning public distrust, especially in areas that have been hard-hit by lead problems in the past. However, just as water customers are changing their simple trust of the water that comes out of their tap, so too may water utilities change their process to help their transition from lead service lines to safe, lead-free supply lines. Instead of being stuck in the old way of digging huge trenches to replace a single, small service line that has so much potential for human illness, an easier option is available to get the job done quickly with a lower overall cost and inconvenience than in the past.

New Concept Tools’ dedication to developing stronger, safer, easier tools for the water utility industry has been fulfilled in the Service Line Puller Kits. These kits provide you with almost everything you need to pull old lead service lines out and install safe, new, lead-free service lines at the same time. All you need to provide is the power in terms of a backhoe or similar heavy equipment, and manpower to manage both ends of the service line. Instead of wasting your community’s time and money in a long, drawn-out process, you can efficiently and economically replace lead service lines to provide clean, healthy water for the community under your care. Please feel free to contact the experienced professionals at New Concept Tools today to learn more about our Service Line Puller Kit or any of the other innovative tools we’ve developed for water utility use over the years.